Product features

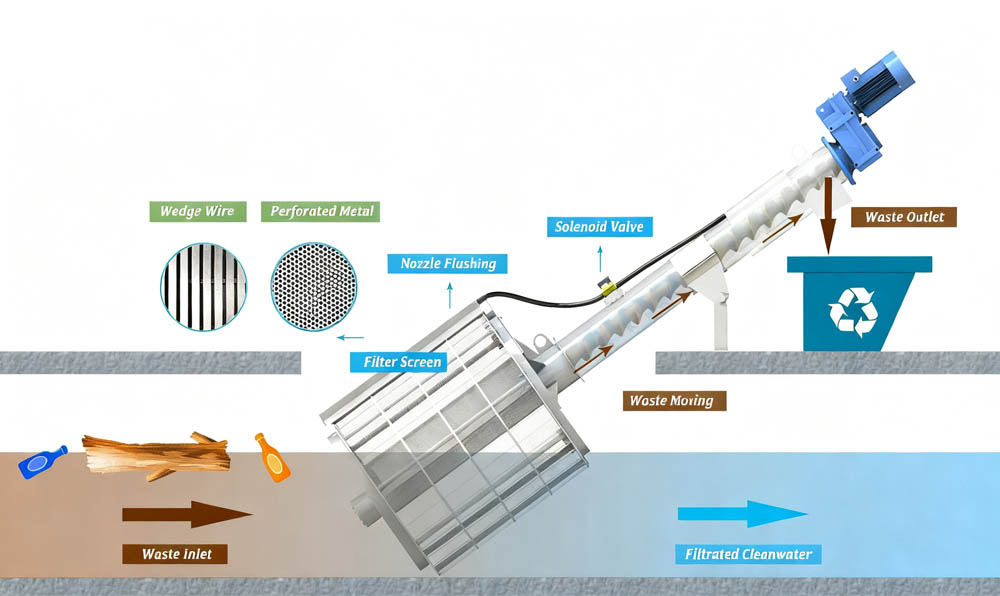

YMX Rotary Drum Screen is an ideal solid/liquid seperation equipment which is polupar in water treatments. It’s very efficient solution for high flow rate and combine the filtration and compacting the sludge process.

The Rotary Drum Screen features a basket screen drum, which can be of perforated metal or wedge wire screen. The drum screen filter the water and rotating with the transport screw, lift the sludge up to outlet with a compacting modulus. The sludge materials are conveyed by a inclined shaft screw until the compacting/dewatering section.

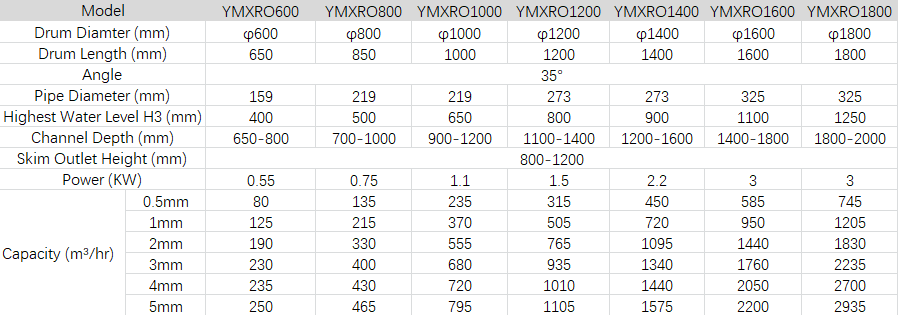

The perforated plate or wedge wire basket filter hole or slot sizes from 0.02 to 0.25-inches (0.5 to 6 mm) . This screen is ideal for either municipal or industrial applications. Captured screenings are compacted, dewatered and washed free of most organic materials to approximately 40 percent solids. Volume is reduced by 50 percent and weight by 67 percent, thereby reducing disposal costs.

Product Parameter

configuration

Advantages of YMX Rotary Drum Screen

■ Low headloss – High separation efficiency

Due to the drum's shape and 35° installation the screen area is much larger than that of a vertical or steeply inclined screen, which results in a low headloss, high separation efficiency and maximum throughput.

Advantages:

■No by-passing

The entire flow enters the screen drum through its open front end and can only leave the drum through its screen area. This prevents plant overflow and guarantees that the screenings are always retained within the screen drum.

■Several functions combined in one system

Perform the functions of screenings removal, transport, washing, dewatering and compaction in a single space saving unit.

■Retrofitting

The design of the RO Screens allows for later modification so that the systems can be adapted to changing requirements. The heating and/or integrated screenings washing can be retrofitted. The bar spacing can also be reduced to meet more stringent requirements.

■Low maintenance

No lubrication. Regular checking and visual inspection are sufficient.

■Dual spray wash system returns organic material to the wastewater flow

■Simple design with a single drive minimizes maintenance cost